How it Works: Crushers, Grinding Mills and

2017年6月2日 Rock crusher. Material is reduced by crushers and grinders by fracturing, which takes place when the material is put under stress by

Consulter un spécialiste

Crushing and Screening Handbook - AusIMM

2021年6月24日 quality rock materials for demanding construc-tion projects, such as bridges. Crusher automation – ensures consistent and effi cient operation. Improves

Consulter un spécialiste

Rock Crushing Process in Mining - 911 Metallurgist

2015年7月18日 Coarse crushers or breakers for rock are the jaw crusher, gyratory crusher, single-roll crusher, sledging or slugging roll, HPGR,

Consulter un spécialiste

Types of Rock Crushers Quarry Crushing

2 天之前 The type of rock you plan to focus on processing in your operation will dictate the types of rock crushers you’ll need to include in your crushing circuit. The more you know about the type of rock you wish to

Consulter un spécialiste

(PDF) Design and Construction of Rock Crushing

2018年8月7日 The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals ...

Consulter un spécialiste

Crusher - an overview ScienceDirect Topics

Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone

Consulter un spécialiste

Performance optimization of jaw-type rock crushing

2019年12月11日 The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 13.1×10 5 kN/m 2 and capable

Consulter un spécialiste

SPADE: A rock‐crushing and sample‐handling system developed

2007年6月21日 The rock crusher continuously crushes rocks onto the sample sorter as long as the sample wheel (or carousel) is not commanded to move. If the sample wheel

Consulter un spécialiste

The effect of rock crusher and rock type on the aggregate shape

2020年1月10日 The crushing mechanism and rock type are two main factors that determine aggregate shape properties [19]. Therefore, all rock samples were crushed at the laboratory jaw crusher at the same ...

Consulter un spécialiste

Rock Crusher Plant EasyPLC BRX Do-More ACC

2022年7月4日 Develop a logical sequence of operation: (Step 3 – Rock Crusher Plant EasyPLC) A PLC programmer must know how everything about the sequence and operation of the machine before programming.

Consulter un spécialiste

Gold Mining Rock Crushers and Crushing Plants: A Complete

2023年2月22日 Using quality rock crushers in your gold mining operation can bring a range of benefits, including increased efficiency and reduced operating costs. By investing in quality equipment, you can: Increase your production rate and throughput. Reduce your maintenance costs. Improve the quality of your final product.

Consulter un spécialiste

Effect of crushing mechanism on the shape properties of

2022年1月1日 Fig. 5 shows the mean elongation of the four coarse aggregate fractions for J-C and J-J crushers. The test results showed that the particles obtained from J-C crusher indicated lesser elongation in comparison with J-J crusher. For all the size ranges, American Society for Testing and Materials (ASTM) and Indian Standards (IS) specifies a minimum

Consulter un spécialiste

Gyratory and Cone Crusher - ScienceDirect

2016年1月1日 Figure 5.1 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of rocks produced during blasting in mines. Variations in the design of the breaking head and the mantle have been adopted by different manufacturers. Such variations are adopted from studies on stress distributions of

Consulter un spécialiste

US6783092B1 - Rock crushers - Google Patents

The invention relates to improvements to rock crushers, and in particular rotary impact rock crushers. The crushing chamber may be angled to achieve the desired rock product. Also disclosed is an anvil for use in crusher whereby the anvil position adjustable. The invention enables the operator to dial up a particular rock product specification by adjusting the

Consulter un spécialiste

(PDF) Design and Construction of Rock Crushing Machine

2018年8月7日 This paper describes the design and operation of a high-pressure shear cell (HPSC) capable of pressing granular material against candidate wear surfaces at macroscopic pressures of up to 700 MPa.

Consulter un spécialiste

8 Tips for Crusher Safety Stewart-Amos Equipment Company

2022年10月27日 6. Perform Proper Shutdown Process. Ending the operation of a crusher is an essential part of crusher safety. There are a few steps to follow when shutting down a crusher that every trained worker should follow: Shut down the apron feeder. Ensure equipment is free of material. Shut down the primary crusher.

Consulter un spécialiste

A review of modeling and control strategies for cone

2021年8月11日 Fig. 1 presents a simplified diagram of a cone crusher. Cone crushers consist of a circular outer concave enclosing a cone-shaped mantle that moves eccentrically, see Fig. 1. As the distance between the mantle and concave inner wall increases, rock particles fall; when the distance de-creases, the particles are compressed and crushed.

Consulter un spécialiste

REAL-TIME OPTIMIZATION OF CONE CRUSHERS - CORE

2017年11月22日 1 1 INTRODUCTION The aims of this chapter are to: − Introduce the concept of crushing plants and their importance in a modern society. − Describe the operation of a crushing plant. − Introduce real-time control of crushing plants. − Describe the main challenges associated with crushing plant control. 1.1 CRUSHED ROCK

Consulter un spécialiste

Different types of crushers for distinctive needs

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes

Consulter un spécialiste

SIZE REDUCTION BY CRUSHING METHODS By

2023年12月1日 5 5.2 Gyratory crusher : A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel ...

Consulter un spécialiste

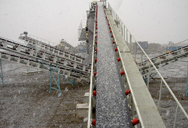

How does the operation of crusher plants work? - LinkedIn

2022年12月23日 The basic operation of most crusher plants include sorting, crushing, and sizing the material. Once these steps are completed, the material is ready for shipment or further processing. Crusher ...

Consulter un spécialiste

United States Environmental Protection Agency General

2015年3月23日 operations. Rock is loaded into bins and sent through screens, sorted for size, and conveyed to one or more rock crushers until all of the raw material is reduced to the desired size. Each crusher machine has associated ... rock crusher processing 5,300,000 tons of material per year, and determined that a 150 foot setback from the

Consulter un spécialiste

Crusher - an overview ScienceDirect Topics

The type of jaw crusher depends on input feed and output product size, rock/ore strength, volume of operation, cost, and other related parameters. Heavy-duty primary jaw crushers are installed underground for uniform size reduction before transferring the ore to the main centralized hoisting system.

Consulter un spécialiste

Simulation and optimization of crushing chamber of gyratory crusher ...

2021年5月1日 During the operation of the gyratory crusher, the crushing chamber is a component that directly interacts with the ore, the performance of the gyratory crusher is mainly determined by its performance [4,5]. ... Discrete element modelling of a rock cone crusher. Powder Technology, Volume 263, 2014, pp. 151-158. Huiqi Li, , Ian Lowndes.

Consulter un spécialiste

Types Of Rock Crushers And When To Use Them - Mellott

2023年1月16日 Knowing what type of rock crusher to use for your project is essential in order to complete projects with maximum efficiency and minimal risk. Understanding the Different Stages of Rock Crushing. Rock crushing is an important part of mining and other industrial operations, and they provide critical resources for construction projects of all

Consulter un spécialiste

Crushers - All crusher types for your reduction needs - Metso

In modern aggregates operations, the use of mobile primary crushers that can move alongside the rock face is, in many cases, the most economical solution. Primary crushing with jaw crushers In terms of the size of the feed opening, the client gets a better return on investment when the primary crusher is a jaw crusher.

Consulter un spécialiste

Optimization of Aggregate Production Circuit through

2022年1月9日 Impact crusher was in operation at the speed of rotor 30 m/s and the calibrating gap width of 80 mm. Particle size distribution of the feed and crushing product for dolomite is

Consulter un spécialiste

A review of modeling and control strategies for cone crushers

2021年8月15日 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Consulter un spécialiste