Rechercher une entreprise - L’Annuaire des Entreprises

Grâce aux filtres de recherche, retrouvez n’importe quelle entreprise, association, ou service public en France. Zone géographique : filtrez par ville, département ou région Dirigeant :

Consulter un spécialiste

Fournisseurs industriels pour mines et carrières – fournisseurs ...

Cette rubrique vous permettra de trouver vos fournisseurs de matériels de carrière par activité. Sélectionnez un produit pour acceder à l'ensemble des fournisseurs, puis cliquez

Consulter un spécialiste

répertoire des fournisseurs de carrières

Répertoire des exposants. Préparez votre visite à l'un de nos salons en explorant les fiches des exposants. Grâce à son moteur de recherche, il est facile de trouver un exposant,

Consulter un spécialiste

Répertoire des carrières territoriales CIG PETITE COURONNE

1 天前 Ce guide pratique organisé en 3 volumes présente en détails, toutes les règles de carrières applicables aux cadres d'emplois de la fonction publique territoriale. Chaque

Consulter un spécialiste

gUIDE POUR LA CARTOgRAPHIE DES EmPLOIS/

2019年2月7日 compétences en complément à l’approche statutaire qui permet de gérer la carrière des agents. • Les collectivités tendent à lier davantage les démarches de

Consulter un spécialiste

Accueil - CNRS Carrières

Votre carrière. Vous accompagner. Parcours professionnels ... Le CNRS recrute en CDD, en dehors des campagnes de recrutement par concours externes, des ingénieurs et techniciens (H/F) dans toutes les branches

Consulter un spécialiste

Fournisseur formation professionnelle - Europages

Fichier pour mailing pour un excellent taux de retour concernant des campagnes d'emailing Rapprochement entre différentes sources fiables et partenaires exclusifs, journaux

Consulter un spécialiste

Suppliers Carrier corporate

Les experts Carrier fournissent des solutions durables, intégrant des produits écoénergétiques, des commandes de bâtiment et des services énergétiques pour les

Consulter un spécialiste

Fournisseurs Chauffage, ventilation et climatisation Carrier

Les spécialistes Carrier proposent des solutions durables, intégrant des produits économiques en énergie, des régulations de bâtiment et des services énergétiques pour

Consulter un spécialiste

Association québécoise des personnes stomisées (AQPS)

Référence vers différentes associations pour les personnes stomisées. Le site Web de l'organisme mentionne aussi des fournisseurs de produits pour la stomie ainsi que de vêtements adaptés. On y retrouve également une liste de stomothérapeutes et d'associations de stomothérapie, ainsi que des renseignements sur le congrès annuel de

Consulter un spécialiste

Votre titre - Ordre CRHA

Pour l’employeur, le titre est gage de confiance. Propulser sa carrière Le titre CRHA CRIA jouit d’une crédibilité et d’une notoriété solidement établies, comme en témoignent 97 % des dirigeants. Par ailleurs, 87 %

Consulter un spécialiste

Volume 3 du Répertoire des carrières territoriales

2021年10月15日 Volume 3 du Répertoire des carrières territoriales. Le Répertoire des carrières territoriales, outil indispensable au quotidien pour tous les agents RH, présente l'ensemble des règles de carrière de la

Consulter un spécialiste

CNFPT

A travers 251 fiches métiers, le répertoire des métiers territoriaux complète la lecture des emplois publics territoriaux au côté d'une approche statutaire et organisationnelle. C’est un outil de gestion des ressources humaines et de gestion prévisionnelle des effectifs, des emplois et des compétences (GPEEC) mis à la disposition des collectivités et des

Consulter un spécialiste

Journées carrière ITAQ

Les journées carrières de l’ITAQ : un événement de réseautage incontournable. Les journées carrière sont des activités d’information et de réseautage qui permettent à nos étudiants de mieux connaître les entreprises et les organisations du milieu agroalimentaire dans lesquelles ils seront appelés à travailler après leur ...

Consulter un spécialiste

Répertoire des carrières territoriales vie-publique

2020年9月25日 Revue. Répertoire des carrières territoriales - n° - 2022. Le Répertoire des carrières territoriales, outil indispensable au quotidien pour tous les agents RH, présente l'ensemble des règles de carrière de la fonction publique territoriale. Disponible sur abonnement uniquement au prix de 94 €. Voir tous les numéros de la revue.

Consulter un spécialiste

Dossier en ligne - Ordre CRHA

Votre dossier en ligne vous permet d'effectuer la gestion de vos coordonnées inscrites dans le répertoire des consultants. A l'intérieur de votre dossier, cliquez sur l'onglet nommé "Répertoire" ainsi que le sous-onglet "Consultants". Sous l'onglet consultants vous retrouverez l'information qui se retrouve dans le répertoire (description ...

Consulter un spécialiste

RNCP27026 - Responsable achats - France Compétences

2021年9月22日 RNCP27026BC05 - Finaliser les engagements fournisseurs par la négociation. - Mettre en œuvre des méthodes de communication interpersonnelle adaptées en situation d’achat à enjeu. - Etre observateur de ses propres comportements et les analyser. - Observer et analyser les réactions de ses interlocuteurs (trices)..

Consulter un spécialiste

Volume 2 du Répertoire des carrières territoriales vie

2022年7月20日 93698 Pantin Cedex. Tél : 01 56 96 82 27 ou 01 56 96 80 94. publications@cig929394. Le Répertoire des carrières territoriales présente, sous forme de classeurs, l’ensemble des cadres d’emplois de la fonction publique territoriale et expose de façon pratique les règles qui régissent le recrutement et la carrière des fonctionnaires.

Consulter un spécialiste

Répertoire des Distinction Fellow - Ordre CRHA

Répertoire des Distinction Fellow. La Distinction Fellow est une mention d’excellence décernée à un CRHA ou CRIA afin de souligner l’ensemble des réalisations d’une carrière, ainsi que sa contribution à l’essor et au rayonnement de la profession.

Consulter un spécialiste

Répertoire de gestion des carrières unique : une 5e étape

2022年9月7日 Répertoire de gestion des carrières unique : une 5e étape franchie avec succès. Mis à jour le 07/09/2022. Mettre en pause Ecouter; ... Il regroupera les données élémentaires de carrière disponibles de tous les régimes, de base et complémentaires. Alimenté automatiquement, il pourra faciliter la mise en œuvre d’évolutions ...

Consulter un spécialiste

Carrière à l’Ordre - Ordre CRHA

Carrière à l’Ordre. Travailler ici, c'est choisir un environnement dynamique et innovateur animé d'un esprit de collaboration unique et d'une volonté constante de dépassement. Joignez-vous à l'équipe de l'Ordre ! Situé au cœur du centre-ville de Montréal, l'Ordre des conseillers en ressources humaines agréés est le cinquième plus ...

Consulter un spécialiste

Constitution de répertoire de fournisseurs et prestataires de

2022年10月9日 Objet de l’appel d’offres : Family Health International (FHI 360) est une organisation internationale de développement, basée au Mali, lance un appel à manifestation d’intérêt afin de recenser des fournisseurs et prestataires légalement constitués et installés au Mali désirant figurer dans son répertoire de fournisseurs agrées.

Consulter un spécialiste

Groupes communautaires: CISSS de Lanaudière

Services de santé et services sociaux - CISSS de Lanaudière. Trouver un organisme communautaire - Répertoire des ressources (MSSS). Find resource in health and social services Other resource

Consulter un spécialiste

Vous voulez lancer un business dans la mode ? Voici comment trouver des ...

2020年6月16日 Voici comment trouver des fournisseurs "propres" TEXTILE ... Recevez nos dernières news Emploi, management, droits, chaque semaine l’actualité de votre carrière.

Consulter un spécialiste

RNCP28134 - Responsable achats - France Compétences

2022年4月21日 Faire le point sur sa carrière. Mon compte formation. Reconversion, démission ... Analyser le marché des fournisseurs actuels et potentiels de l’entreprise ... Arrêté du 07 avril 2017 publié au Journal Officiel du 21 avril 2017 portant enregistrement au répertoire national des certifications professionnelles. Enregistrement pour cinq ...

Consulter un spécialiste

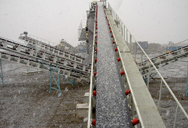

Agnico Eagle Mines Limited - Carrières - Recrutement

Votre avenir commence avec nous. Nous offrons divers postes aux diplômés, aux étudiants des programmes coopératifs et aux stagiaires qui sont talentueux et qui veulent commencer leur carrière dans notre entreprise. Dans votre emploi chez Agnico Eagle, vous serez encouragés à collaborer avec des collègues dans l’ensemble de notre ...

Consulter un spécialiste

Guide des compétences des CRHA et CRIA - CRHA

Le Guide des compétences des CRHA et CRIA permet une définition de la profession RH/RI à la fois ancrée dans la réalité et ouverte sur le futur. Par ce guide, l’Ordre souhaite redéfinir la profession RH/RI pour aujourd’hui et le futur par le biais des compétences, et ce, dans le contexte de transformation des organisations.

Consulter un spécialiste

L'Association mondiale pour l'industrie des attractions - IAAPA

2023年12月8日 Calendrier complet des événements de l'IAAPA Asie-Pacifique pour 2024. Construisez votre marque. Racontez votre histoire. Soutenez votre industrie! Combinez la puissance de votre marque avec l'influence d'opportunités de parrainage personnalisées.

Consulter un spécialiste

Agnico Eagle Mines Limited - Exploration

Agnico Eagle vise à améliorer la qualité et la valeur de son entreprise. Notre équipe de géologues hautement qualifiés est déterminée à faire croître notre filière de projets d’exploration et de mise en valeur en se concentrant sur les régions stables sur le plan politique et reconnues pour leur production d’or où les projets et les mines peuvent servir

Consulter un spécialiste